Ad

Ad

How to Save Your Tractor Clutch from Early Damage: Easy Tips for Long Life and Smooth Farming

Tractors play a vital role in Indian agriculture, from ploughing and sowing to transporting crops. However, many farmers often overlook one of the most important parts of their tractor, the clutch. This component directly affects the tractor’s power, performance, and efficiency. A damaged clutch not only hampers your work but also leads to costly repairs. That’s why it’s essential to understand how to care for your tractor clutch and avoid early damage.

Also Read: Monsoon Tractor Maintenance Guide: Keep Your Tractor Safe and Productive in Rainy Season

In this article, you will learn about:

Common signs of clutch failure

Daily checks to prevent damage

Easy maintenance habits for long life

Practical tips for operating under heavy loads

What Is the Role of a Tractor Clutch?

The clutch connects and disconnects the tractor's engine from the transmission system, allowing you to change gears smoothly and control power to the wheels. It helps regulate engine power during different farming tasks. If the clutch fails, the tractor loses efficiency, becomes harder to drive, and may stop working altogether.

Common Symptoms of Clutch Failure in Tractors

Recognizing early signs of clutch problems can save you from expensive repairs. Look for these warning signals:

1. Power Loss: If your tractor feels weaker during heavy work or cannot handle its usual load, the clutch may be slipping. This happens when the clutch plates wear out and can’t grip properly.

2. Difficulty Shifting Gears: Trouble shifting gears, especially if there is a jerk or the gears stick, means the clutch plates are likely worn and may need replacement.

3. Tight or Loose Clutch Pedal: If the clutch pedal feels either too stiff or too loose, the clutch system may be out of balance. This often indicates issues with the clutch assembly.

4. Burning Smell: A burning smell, especially near the gearbox, is a clear sign that the clutch plates are overheating due to friction and may soon fail.

Also Read: Solis 4515 E vs Mahindra 575 DI XP Plus: Which Tractor Offers Better Value for Farmers?

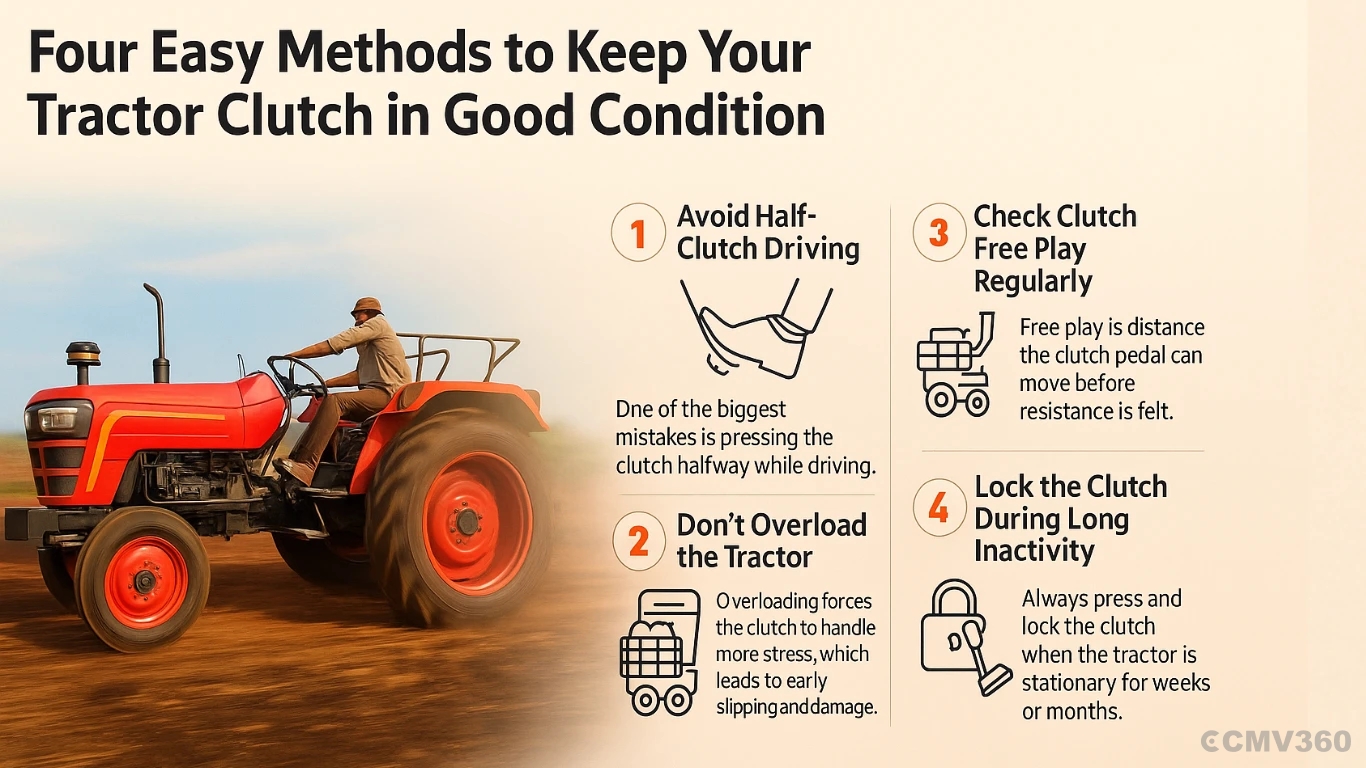

Four Easy Methods to Keep Your Tractor Clutch in Good Condition

Following these practical and simple habits can significantly extend the life of your clutch.

1. Avoid Half-Clutch Driving: One of the biggest mistakes is pressing the clutch halfway while driving. This causes continuous friction between the clutch plate and flywheel, leading to faster wear and tear. Always fully press the clutch when changing gears and release it completely after.

2. Don’t Overload the Tractor: Overloading forces the clutch to handle more stress, which leads to early slipping and damage. During heavy tasks, use low gears and avoid frequent gear changes. This helps reduce pressure on both the clutch and transmission.

3. Check Clutch Free Play Regularly: Free play is the distance the clutch pedal can move before resistance is felt. Ideally, it should be around 1 to 1.5 inches. Check it every 15–20 days. If it’s not within this range, get it adjusted immediately to avoid long-term damage.

4. Lock the Clutch During Long Inactivity: During the off-season or monsoon, when the tractor is unused for long periods, the clutch plates can get stuck. Always press the clutch pedal and lock it if the tractor will be stationary for weeks or months. Many modern tractors come with a built-in clutch lock feature.

Practical Tips for Daily Use to Avoid Clutch Damage

1. Do Not Ride the Clutch: Resting your foot on the clutch while driving causes unnecessary friction. Remove your foot completely from the clutch pedal when not shifting gears.

2. Smooth Gear Shifts: Always press the clutch fully when changing gears and release it gradually. Avoid sudden gear changes or high-speed starts, especially under load.

3. Avoid High RPM Starts: Starting the tractor with too much acceleration causes the clutch to overheat. Use a moderate engine speed for smoother engagement and longer clutch life.

4. Shift to Neutral When Stopped: If the tractor is stopped at a signal or during fieldwork, do not keep the clutch pressed. Shift to neutral to avoid extra pressure on the clutch.

Also Read: Is Your Tractor Giving Low Mileage? Follow These 10 Easy Tips to Save Fuel and Increase Profit

Special Precautions for Heavy Load Operations

Operating tractors under heavy loads requires special care to protect the clutch:

Use Low Gears on Slopes: When moving uphill or with heavy equipment, use lower gears for better power transfer and less clutch stress.

Use Handbrake on Inclines: On slopes, use the handbrake to hold the tractor. Find the clutch's bite point and then release the handbrake to prevent rollback and clutch slipping.

Avoid Frequent Stops: Continuous start-stop actions increase clutch usage. Plan work to reduce frequent halts.

Avoid pressing the Brake and Clutch Together: Use both pedals together only when necessary to avoid unwanted clutch engagement.

Simple Daily Checks to Extend Clutch Life

1. Check Clutch Pedal Free Play: Look for correct pedal movement before resistance. Follow your tractor’s manual for exact settings.

2. Smooth Pedal Operation: The clutch pedal should move smoothly and return easily. Any stiffness, noise, or sticking means a problem.

3. Look for Leaks: Oil or hydraulic fluid leaks near the clutch area can cause slipping and need immediate attention.

4. Listen for Unusual Noises: Any strange sounds when using the clutch may indicate internal damage. Get it checked by a mechanic.

5. Inspect for Visible Damage: Look for cracked, bent, or worn clutch cables or linkages. Replace damaged parts early.

6. Keep the Clutch Area Clean: Mud, dirt, and oil can block movement. Clean the area around the clutch regularly.

7. Follow Lubrication Schedules: Lubricate moving parts like clutch linkage and pivot points as per the manual.

Professional Maintenance and Clutch Adjustment

Schedule Regular Checkups: Get the clutch system checked by a professional every 50 hours of use or as recommended by your tractor manufacturer.

Replace Worn Components Early: Timely replacement of worn parts avoids bigger damage and ensures smoother operation.

Follow Manufacturer’s Guidelines: Each tractor model is different. Always follow your user manual for correct settings, maintenance routines, and clutch care.

CMV360 Says

Maintaining your tractor’s clutch is easy and requires just a few simple habits like avoiding half clutching, not overloading the tractor, regularly checking free play, and locking the clutch during long breaks. These small efforts, along with timely maintenance, can significantly reduce repair costs and prevent downtime during farming. By following these tips, you not only extend the life of your tractor clutch but also ensure smooth and efficient operation for years. Share these helpful practices with fellow farmers to promote better tractor care and boost productivity across the farming community.

Features & Articles

Single and Double Clutch in Tractors: Which One Is the Right Choice for Your Farming Needs?

Compare single vs double clutch tractors. Learn differences, benefits, and which clutch suits your farming needs for better efficiency, comfort, and long-term value....

02-Feb-26 12:22 PM

Read Full NewsTop 10 Tractor Brands in India 2026

Explore the top 10 tractor brands in India for 2026 with prices, features, and uses. A simple guide to help farmers choose the right tractor....

23-Jan-26 11:48 AM

Read Full NewsTop 5 Mahindra Tractors Under ₹5 Lakh for Small Farmers in India (2026)

Explore the best Mahindra tractors under ₹5 lakh with prices, features, and comparisons. A simple 2026 guide for small farmers seeking affordable, reliable, and fuel-effi...

22-Jan-26 01:03 PM

Read Full NewsMukhya Mantri Ladli Behna Yojana 2026: Complete Updated Guide to Benefits, Eligibility, Application Process, and Impact

Complete guide to Mukhya Mantri Ladli Behna Yojana 2026 covering benefits, ₹1,500 monthly assistance, eligibility rules, application process, DBT payments, latest updates...

21-Jan-26 12:24 PM

Read Full NewsSub-Mission on Agricultural Mechanization (SMAM): Complete Guide

Complete guide to Sub-Mission on Agricultural Mechanization covering objectives, subsidy structure, eligibility, benefits, funding pattern, and online application process...

16-Jan-26 06:26 AM

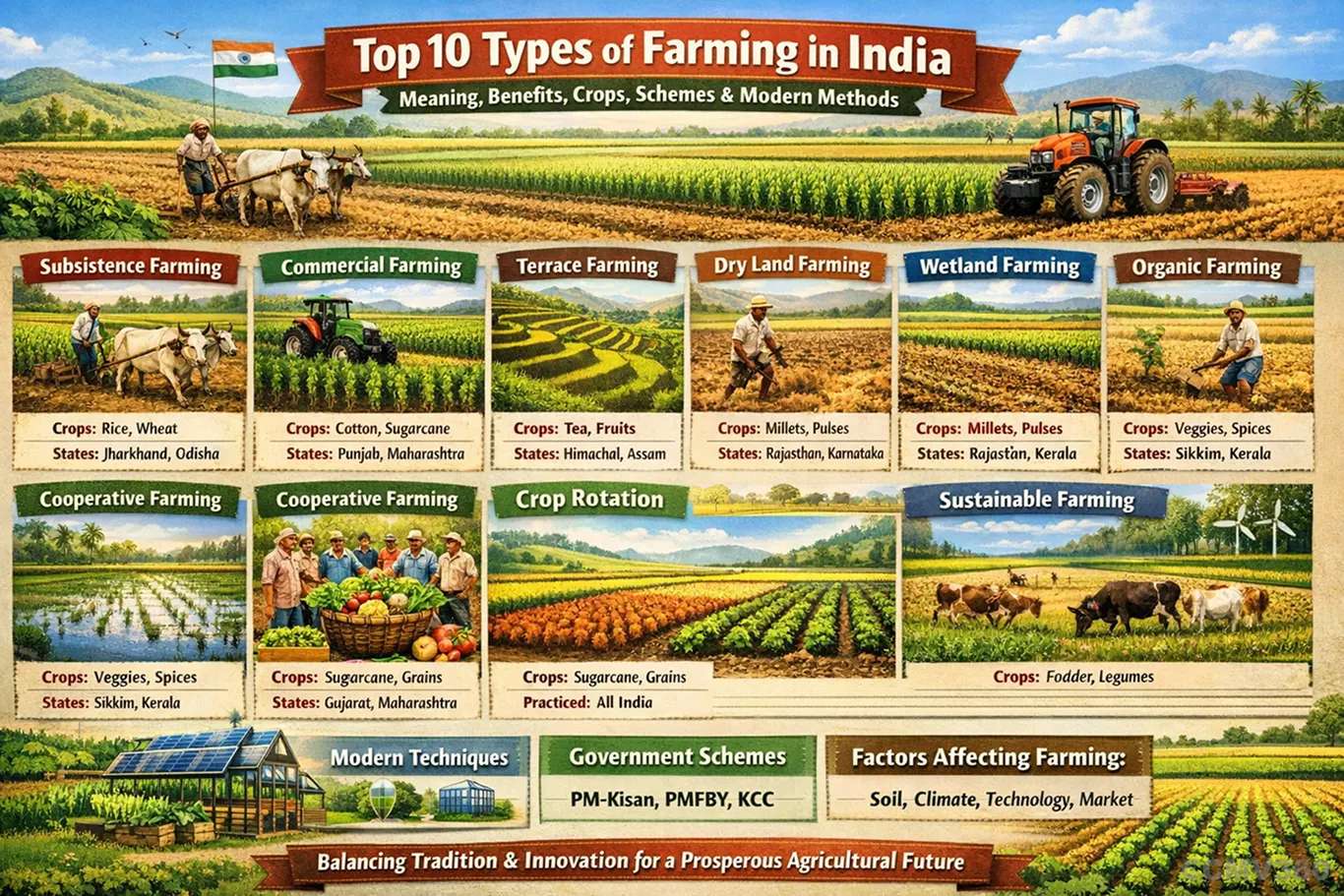

Read Full NewsTop 10 Types of Farming Practiced in India 2026: Explained with Crops, Benefits and Schemes

Explore the top 10 types of farming in India with meaning, benefits, crops grown, modern methods, key factors, and government schemes supporting sustainable and profitabl...

15-Jan-26 09:43 AM

Read Full NewsAd

Ad

As featured on:

Registered Office Address

Delente Technologies Pvt. Ltd.

M3M Cosmopolitan, 12th Cosmopolitan,

Golf Course Ext Rd, Sector 66, Gurugram, Haryana

pincode - 122002