Ad

Ad

Scania Becomes First Truck Maker to Use Reused Parts in Main Assembly Line

Key Highlights

- Scania integrates remanufactured components in the main assembly line.

- 50% less material and 45% fewer emissions.

- Gearbox passed strict quality tests, matching new standards.

- The project aims to support circular manufacturing.

- Collaboration with KTH and Scandinavian Transmission Service AB.

In a groundbreaking achievement, Scania has become the world's first truck manufacturer to integrate the reused components directly into its main assembly line. This major milestone was achieved as part of the iReGear project, which aims to make truck production more sustainable. The project was carried out in collaboration with KTH Royal Institute of Technology and Scandinavian Transmission Service AB, and it was funded by Vinnova, Sweden's innovation agency.

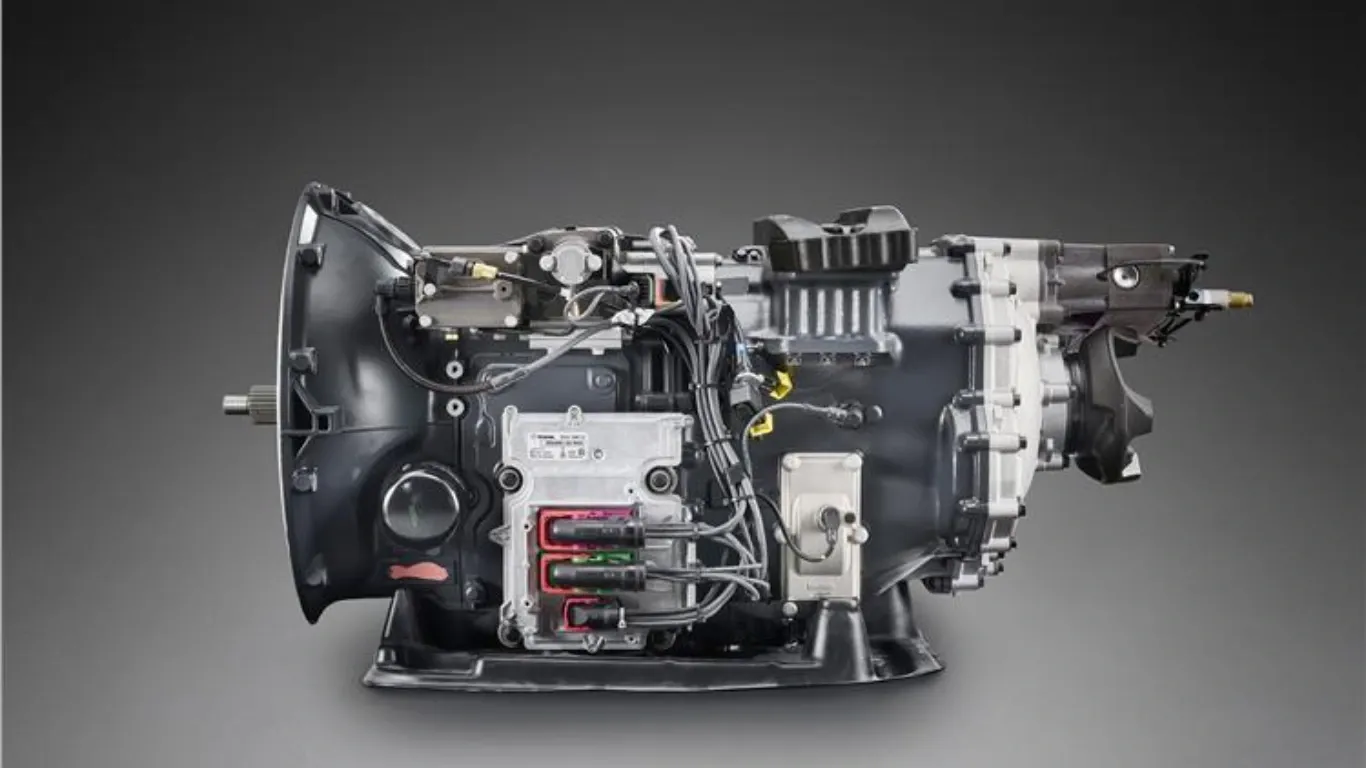

Gearbox Remanufacturing

The iReGear project, which ran from September 2023 to May 2024, focused on remanufacturing gearboxes. Unlike traditional methods that rely solely on new parts, this project reused old parts to create a gearbox that passed all the rigorous quality checks required for new components. The gearbox underwent the same tests as a new one, meeting over 100 quality and function parameters. The results confirmed that the remanufactured gearbox was "as good as new."

Environmental Benefits

One of the most significant achievements of this project is its environmental impact. By reusing the parts, the remanufactured gearbox uses about 50% less material and produces 45% fewer carbon emissions compared to the gearboxes made entirely from new components. This demonstrates just how remanufacturing can reduce waste and also contribute to a more sustainable future for the automotive industry.

Remanufacturing for a Circular Economy

Remanufacturing, which involves using old parts to create new products, is gaining attention as a key strategy in achieving climate goals and supporting a circular economy. This process can help to reduce the shortage of resources and is also seen as a more sustainable approach to manufacturing. However, until now, remanufacturing in the automotive industry has mostly been limited to aftermarket parts. The success of the iReGear project paves the way for remanufactured components to be integrated into new vehicle production lines, marking a shift towards more sustainable manufacturing practices.

Industry Leader’s Take

Fredrik Nilzén, Head of Sustainability at Scania, expressed his excitement about the project, stating, "This remanufactured gearbox is a great example of how we can make heavy vehicle production more sustainable and circular without sacrificing quality."

Assistant Professor Farazee Asif from KTH added, "This project shows that it’s possible to integrate remanufacturing into regular production. It’s a big step towards creating Circular Manufacturing Systems that use fewer resources and produce fewer emissions."

Ola Stålebo, CEO of Scandinavian Transmission Service AB, praised the collaboration, saying, "We’ve been remanufacturing gearboxes for over 50 years, but this project proves that remanufactured parts aren’t just for aftermarket use. This could become the standard for the future."

The Future of Sustainable Truck Production

Scania’s achievement highlights the potential for the wider adoption of remanufacturing in the truck industry. By integrating reused parts into the main assembly line, this project demonstrates that sustainable practices can be adopted without compromising quality or performance. This approach could lead to more circular manufacturing systems, helping the automotive industry reduce its environmental impact while maintaining high standards of production.

Also Read: Apollo Tyres’ Chennai Plant Wins Energy Management Insight Award

CMV360 Says

Scania's success with the iReGear project marks an important step toward a more sustainable future for heavy vehicle manufacturing. By reusing components and reducing material usage and emissions, the company is leading the way in making truck production more environmentally friendly. This project could inspire the entire automotive industry to embrace similar practices, helping to create a cleaner, more sustainable transport sector.

News

Tata Motors Records 42,940 Commercial Vehicle Sales in February 2026

Tata Motors sold 42,940 commercial vehicles in February 2026, reporting 32% year-on-year growth driven by strong domestic demand and steady export performance across key ...

02-Mar-26 06:15 AM

Read Full NewsMahindra & Mahindra Ltd. Reports 17% Growth in Domestic CV & 3-Wheeler Sales in February 2026

Mahindra records 17% domestic CV and 3W growth and 11% export rise in February 2026 with total sales reaching 97,177 units....

02-Mar-26 05:17 AM

Read Full NewsIndonesia Pauses Massive Import Order From Tata, Mahindra

Indonesia suspends $1.5 billion Tata and Mahindra vehicle import plan amid political and industry concerns....

27-Feb-26 02:13 PM

Read Full NewsTata Motors Signs MoU with V.O. Chidambaranar Port to Deploy 40 Hydrogen Trucks at Tuticorin

Tata Motors signs MoU with VOC Port to deploy 40 hydrogen H2 ICE trucks, backed by government funding and new hydrogen infrastructure at Tuticorin port....

26-Feb-26 12:03 PM

Read Full NewsOlectra Greentech Limited Appoints Dr Allabaksh Naikodi as Head - EV Systems to Strengthen Powertrain and Battery Technology

Olectra Greentech strengthens EV tech by appointing Dr. Allabaksh Naikodi as Head - EV Systems, enhancing powertrain, battery systems, and innovation across electric buse...

25-Feb-26 07:21 AM

Read Full NewsNoida International Airport Awards Major Ground Mobility Contract to Mann Fleet Partners Limited to Strengthen Passenger Connectivity

Noida International Airport appoints Mann Fleet for rental cars and shuttle services, boosting passenger connectivity across Delhi-NCR ahead of its operational launch....

25-Feb-26 06:03 AM

Read Full NewsAd

Ad

Latest Articles

Best Tata Magic Buses in India 2026

25-Feb-2026

Mahindra Commercial Vehicles in India 2026

24-Feb-2026

Diesel vs Electric Trucks in India 2026: Detailed Comparison of Cost, TCO, Subsidies, Charging & Best Choice for Fleets

21-Feb-2026

Top 10 Buses in India 2026

19-Feb-2026

Top 10 Tata Mini Truck Price List in India 2026

18-Feb-2026

Best Tata Electric Trucks in India 2026

16-Feb-2026

View All articles