Ad

Ad

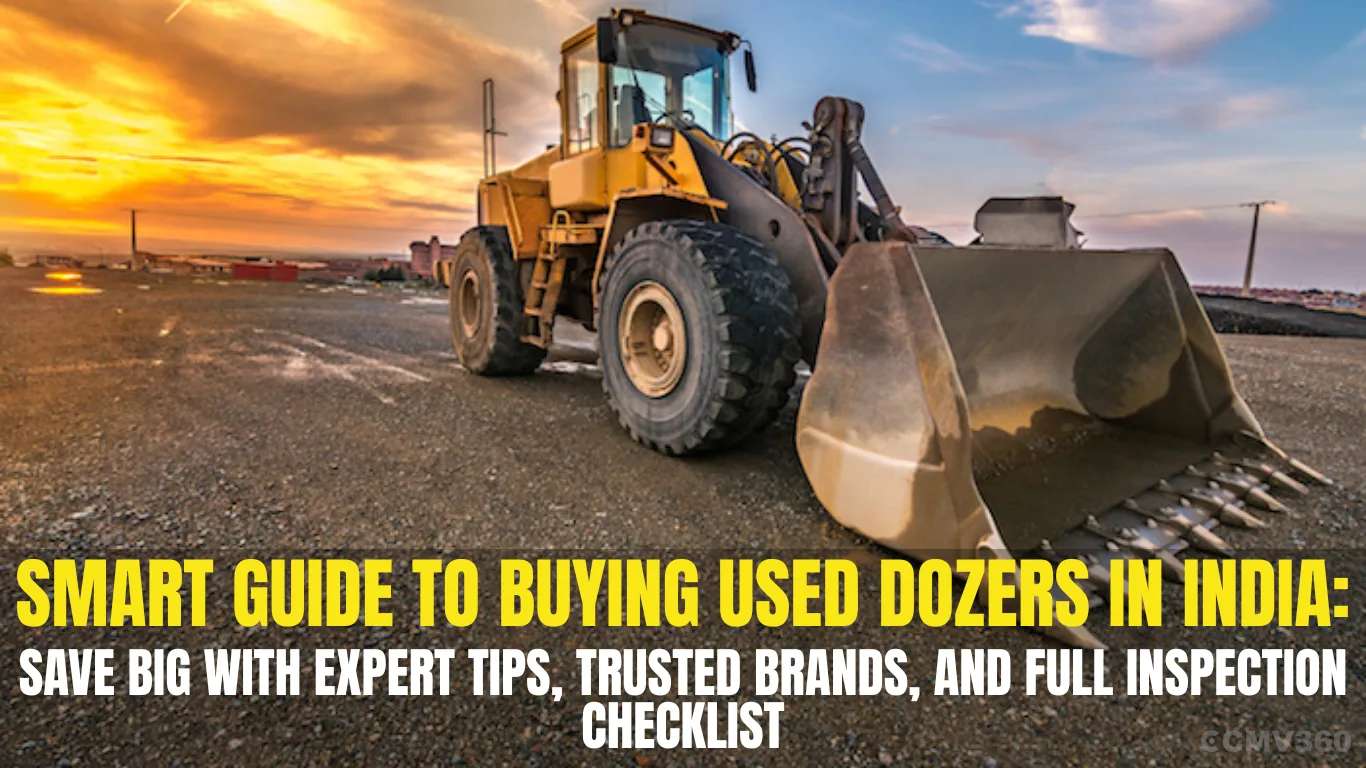

Smart Guide to Buying Used Dozers in India: Save Big with Expert Tips, Trusted Brands, and Full Inspection Checklist

Share

98,676 Views

Posted By Robin Kumar Attri on 27-Oct-2025 09:47 AM

The demand for construction and mining equipment in India is growing faster than ever. With large-scale projects taking place in roads, railways, mining, and real estate, the need for powerful and reliable machinery has skyrocketed. However, the high cost of brand-new machines often becomes a challenge for contractors, especially small and medium-sized businesses. This is why used dozers (also known as bulldozers) have become a smart and popular choice in the Indian market.

Brands like Caterpillar, Komatsu, JCB, BEML, Liebherr, CASE Construction, and Hindustan dominate this segment. They manufacture durable machines that maintain their performance and strength even after years of use. Buying a second-hand dozer from such trusted brands can save a lot of money while ensuring efficient performance for various jobs like land clearing, road building, mining, and heavy earthmoving

Still, purchasing a used dozer is not as simple as buying a new one. It requires careful inspection, research, and understanding of both benefits and potential risks. This article provides a complete, easy-to-understand, and User-friendly guide on how to buy used dozers in India, including inspection tips, advantages, disadvantages, and smart buying practices.

Why Contractors Prefer Used Dozers

For many contractors in India, choosing a used dozer is a strategic investment decision. Whether it’s a small builder working on local projects or a medium enterprise handling infrastructure development, second-hand dozers offer multiple advantages such as:

1. Cost-Effective Investment: The biggest reason for buying a used dozer is affordability. A brand-new Caterpillar D6 or Komatsu D65EX-18 Dozer can cost several lakhs or some of the larger ones may even cost crores, which may not fit the budget of every company. A used machine, however, can cost 50% to 70% less while still delivering excellent performance. This allows contractors to save funds for other operational expenses such as fuel, manpower, and spare parts.

2. Immediate Availability: When you order a new machine, there is often a long waiting period due to manufacturing and delivery schedules. In contrast, a used dozer can be deployed almost immediately. This makes it ideal for projects with tight deadlines.

3. Proven Durability: Dozers from brands like Komatsu, CAT, BEML, and CASE are known for their robust design and long service life. Many models can operate efficiently for decades if maintained properly. When you buy a well-maintained used unit, most of the depreciation has already occurred, making it a low-risk, high-value purchase.

4. Budget Flexibility: Buying used equipment allows small and medium businesses to expand their fleet without taking heavy loans or exhausting their capital. This flexibility helps in taking up multiple contracts simultaneously.

Disadvantages of Buying a Used Dozer

While the benefits are appealing, it’s equally important to also consider the drawbacks before investing in a second-hand dozer. As ignoring these factors can result in unexpected expenses and reduced productivity later.

1. Risk of Hidden Mechanical Issues: Used dozers can look fine from the outside but might have internal problems such as engine wear, hydraulic leaks, or transmission damage. Without a thorough inspection, these issues may remain unnoticed until the machine starts showing faults on site. Repairs for such problems can be expensive and time-consuming.

2. Frequent Maintenance Needs: Older dozers need more frequent servicing and replacement of parts. Components like undercarriage parts, hydraulic pumps, and gear assemblies experience natural wear over time. Maintenance costs for older models are generally higher than for new machines.

3. Lack of Modern Features: Newer dozers from brands like Caterpillar, John Deere, and Komatsu now come with advanced GPS systems, telematics, and fuel-efficient engines. Older models usually lack these features, which can lead to lower operational efficiency and higher fuel consumption.

4. Limited Warranty and Support: Most second-hand dozers come without manufacturer's warranty. Any repairs or replacements become the buyer’s responsibility. Additionally, for discontinued models, finding spare parts can be difficult.

5. Low Resale Value: Used machines already have depreciated value, and with each passing year, their resale price decreases further. Buyers must consider this if they plan to resell the dozer later.

Also Read: Smart JCB Mileage Hacks to Save More on Fuel

Essential Considerations Before Buying

Before finalizing the deal for a used dozer, buyers should evaluate several important factors. A thoughtful purchase reduces the risk of unexpected costs and ensures long-term reliability.

1. Check for Hidden Issues: Appearances can be deceiving. Even a well-painted dozer can hide internal engine or hydraulic system issues. Always perform a physical inspection and, if possible, hire a qualified mechanic or technician to evaluate the machine.

2. Estimate Maintenance Requirements: Used machines often require more frequent oil changes, filter replacements, and part upgrades. Estimate these expenses in advance to plan your operational budget accurately.

3. Verify Service Records: A dozer with a complete service history is always a better option. Check the maintenance log to ensure that timely oil changes, filter replacements, and part repairs were carried out. This also gives insight into how the machine was handled by the previous owner.

4. Review Ownership and Legal Papers: Ensure that the seller provides authentic ownership documents such as RC, invoice, insurance, and NOC if applicable. This prevents any legal issues or disputes after the purchase.

5. Consider Spare Parts Availability: Some older or discontinued models may have limited spare part availability. Before buying, confirm that the necessary parts are easily available through local dealers or online suppliers.

Key Areas to Inspect Before Purchasing a Used Dozer

A detailed inspection is the most important part of buying a used dozer. Even a small mechanical problem can result in big expenses later. The following checklist will help ensure a thorough examination:

1. Engine and Fluids

Check for oil leaks, coolant leaks, or smoke from the exhaust.

Inspect the oil level and color, milky or black oil may indicate contamination or poor maintenance.

Listen for unusual noises when the engine starts; knocking or rattling sounds can signal internal wear.

Review service records for past engine overhauls or part replacements.

2. Hydraulic System

Inspect hydraulic hoses, seals, and cylinders for any leaks or damage.

Test the hydraulic system by raising and lowering the blade to check for smooth, consistent movement.

Look for jerky operation, which might indicate air in the hydraulic lines or a weak pump.

3. Undercarriage and Tracks

Check for uneven wear on rollers, chains, and sprockets.

Measure track tension and adjust if necessary.

Excessive rust or loose bolts are warning signs of poor maintenance.

Replacing an undercarriage is costly, so make sure this area is in good condition.

4. Blade and Frame Structure

Inspect the blade edges for cracks, dents, or excessive wear.

Look for any welding marks or structural repairs on the main frame, as these may indicate previous damage.

Ensure the blade operates evenly and maintains good ground contact.

5. Transmission and Steering

Test the machine under load to check smooth gear shifting.

Poor steering response or difficulty in changing directions can signal hydraulic or transmission issues.

Listen for grinding or clunking sounds during operation.

6. Cabin and Controls

Check the dashboard instruments, switches, lights, and gauges for functionality.

Make sure the air conditioning, seat comfort, and visibility are satisfactory for the operator.

Test joystick sensitivity and control accuracy for ease of operation.

7. Electrical System

Inspect the battery terminals, wiring, and alternator.

Ensure the machine starts easily and maintains a steady electrical supply.

8. Tires or Track Pads

Examine the condition of pads or tires (depending on the dozer type).

Uneven wear can suggest poor alignment or excessive usage on one side.

Also Read: JCB 3DX Vs JCB 2DX: Which Backhoe Loader Should You Choose?

Trusted Brands for Used Dozers in India

India’s construction and mining market features several globally recognized brands known for durability, resale value, and service network. Some of the top options include:

Caterpillar (CAT): Renowned for models like CAT D5 and CAT D6, known for reliability and powerful engines.

Komatsu: Offers long-lasting machines such as Komatsu D65 and D155, popular in mining and earthmoving operations.

BEML (Bharat Earth Movers Limited): India’s homegrown manufacturer producing heavy-duty dozers suited for mining and defence.

Liebherr: Known for advanced hydraulic systems and operator-friendly design.

CASE Construction: Offers compact, fuel-efficient dozers perfect for smaller contractors.

John Deere: Delivers performance and comfort with strong global service support.

JCB and Hindustan: Reliable for mid-range operations and easily available spare parts.

Choosing a machine from these brands ensures better after-sales support, higher parts availability, and dependable performance, even when purchased second-hand.

Where to Buy Used Dozers in India

Today, there are multiple channels through which you can buy used construction machinery in India:

Authorized Dealers: Many brands have certified pre-owned programs, ensuring quality checks and a limited warranty.

Online Platforms: Websites like Infra Bazaar, Equipment Planet, and Machinery Mart list used dozers with photos, prices, and inspection reports.

Local Auctions: Companies or government agencies often auction old dozers at reasonable rates.

Direct Sellers: Buying directly from contractors can be cheaper, but always verify ownership documents and condition reports.

Negotiation and Pricing Tips

Compare Market Prices: Check similar models prices online to know the fair value.

Request Inspection Reports: Always ask for a third-party inspection certificate before finalizing.

Include Transportation Costs: If the dozer is located in another state, include freight and registration transfer costs in your total budget.

Negotiate Based on Condition: Use inspection findings like worn tracks or hydraulic leaks as leverage for a better deal.

Maintenance After Purchase

Once you purchase a used dozer, regular maintenance is the key to maximizing its performance and life span. Follow these simple tips:

Change all fluids and filters immediately after purchase.

Schedule preventive maintenance every 250 to 500 hours of operation.

Keep the undercarriage clean after each use to prevent wear.

Use genuine parts from authorized dealers for longer reliability.

Train operators on proper handling to minimize damage and fuel waste.

Also Read: JCB Telehandler: Boosting Productivity with Stage 5 Innovation

Final Tips for a Smart Purchase

Buying a used dozer in India can be a smart and profitable decision if done carefully. The goal is to find a machine that balances performance, reliability, and price. Always prioritize inspection, documentation, and service history before finalizing the deal.

Working with trusted brands like CAT, Komatsu, BEML, CASE, and Liebherr ensures better resale value and long-term support. Choose dealers who offer inspection reports, transparent records, and post-sale service.

With India’s infrastructure growth continuing rapidly, the need for powerful and affordable machinery will keep rising. By investing wisely in a well-maintained used dozer, contractors can expand their operations, reduce costs, and stay competitive in a fast-developing market.

Ad

Articles

JCB vs SANY: Which Excavator Saves More Money, Fuel & Time? Full Breakdown!

A simple, detailed JCB vs SANY excavator comparison covering price, features, fuel efficiency, technology, service support, machine types, and best use cases to help cont...

25-11-2025 10:11 AM

Read Full NewsCan Electric and Hybrid Construction Equipment Replace Diesel Machines in India?

Can electric and hybrid construction equipment replace diesel machines in India? Explore benefits, challenges, power, cost, and future adoption trends in India’s growing ...

19-11-2025 06:11 AM

Read Full NewsHow Tata Hitachi Construction Machinery Company Ltd. is Powering India’s Shift to Electric Construction Equipment

Tata Hitachi drives India’s shift to electric construction equipment with eco-friendly excavators, lower costs, and zero emissions, setting new standards for sustainable ...

22-10-2025 09:10 AM

Read Full NewsJCB Telehandler: Boosting Productivity with Stage 5 Innovation

Explore JCB telehandler price, on-road cost, EMI options, loan calculator, and Stage 5 technology benefits. Learn how JCB boosts productivity, saves costs, and ensures cl...

16-09-2025 09:09 AM

Read Full NewsSmart JCB Mileage Hacks to Save More on Fuel

Discover smart tips to improve JCB mileage, reduce diesel costs, and boost efficiency. Learn about JCB models, fuel-saving practices, maintenance, and operator techniques...

18-08-2025 10:08 AM

Read Full NewsJCB 3DX Vs JCB 2DX: Which Backhoe Loader Should You Choose?

Compare JCB 3DX vs 2DX backhoe loaders, features, price, and EMI options to choose the best machine for your needs....

31-07-2025 12:07 PM

Read Full NewsAd